Services

Trust Apex for Every Phase of Your Project

We specialize in the planning, design, installation and maintenance of industrial and commercial refrigeration systems, process heating and cooling systems, domestic and industrial boilers, and traditional HVAC equipment. We also focus on energy efficiency and post-installation maintenance for every project, with the ultimate goal of achieving the lowest operational costs for our customers.

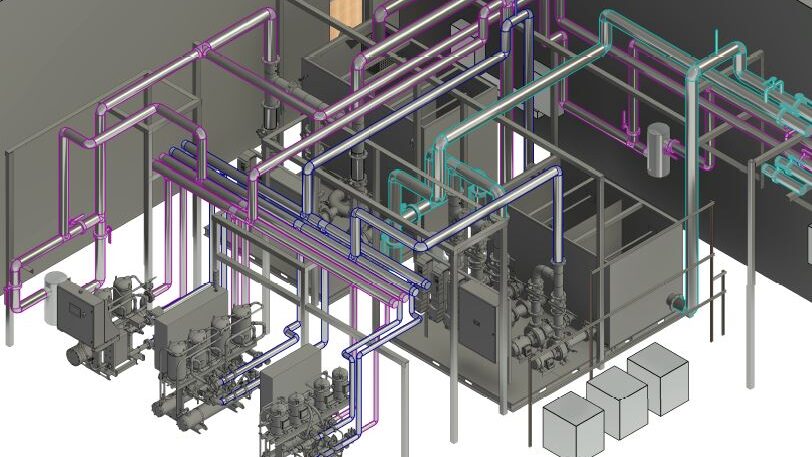

Planning & Design

We have the in-house designers, mechanical capabilities and industry knowledge to plan and design the right industrial refrigeration system for your company that fits within your budget.

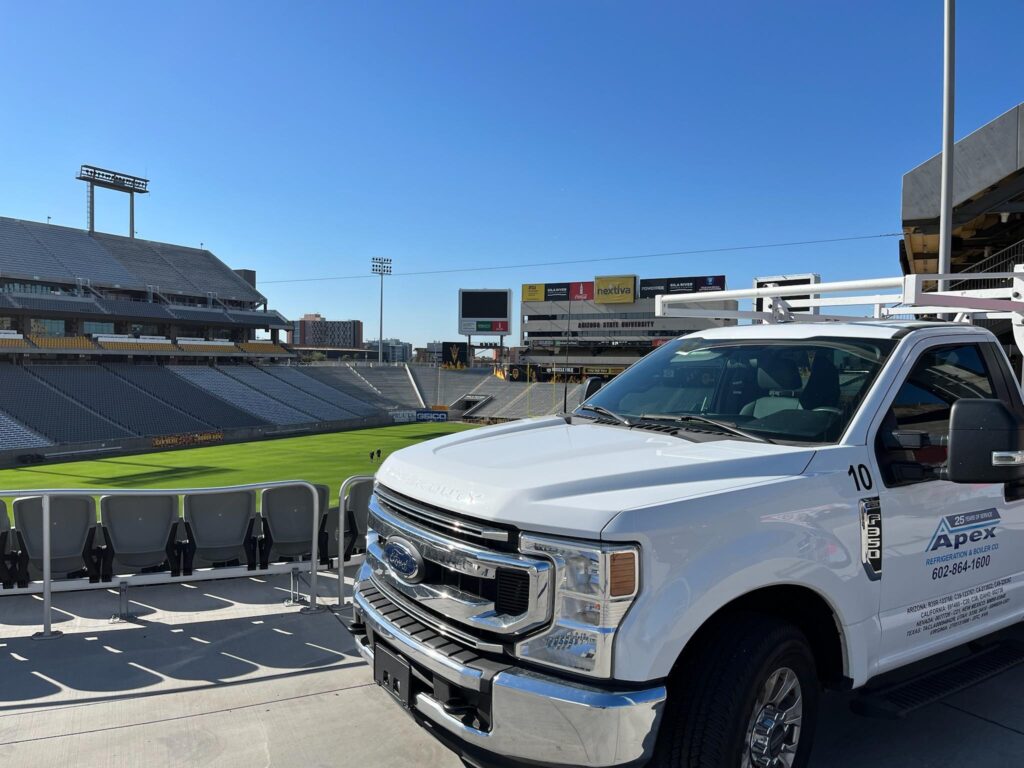

Projects & Installation

We have over 40 years of construction and installation expertise, including training in ammonia, halocarbon refrigerants, steam, water and HVAC systems. Plus, all our staff is OSHA trained and certified, and works to uphold Apex’s standards of high-quality workmanship combined with our customer-first approach to business.

Emergency Service

We keep our emergency service staff on call 24/7 because we know malfunctions and mishaps can happen any time of day. When something goes wrong, the Apex emergency team can assist your facility.

Rebuild Services

We partner with industry-leading rebuild shops that specialize in compressor rebuilds and we have the ability to rebuild some compressors on-site in the field. Need us to come to your site to disconnect/reconnect the compressor to your system? No problem. We also offer hauling to and from our rebuild partners.

Partner With the Experts in Refrigeration

At Apex, we’re dedicated to developing custom solutions that fit your company’s unique needs while providing a level of service that’s unmatched in the region. Whenever you need us, we’ll be there.